Application: Pedal test stand

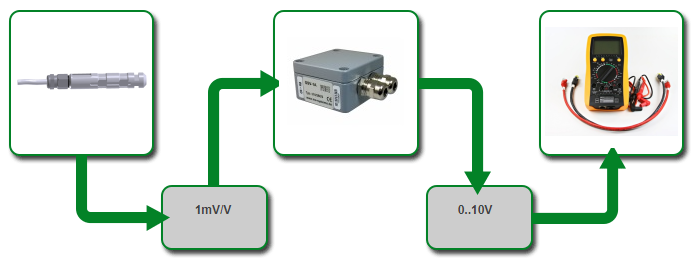

System interface: External amplifier with analogue interface

Loadpin MB664 Amplifier GSV-1A Multimeter

Application:

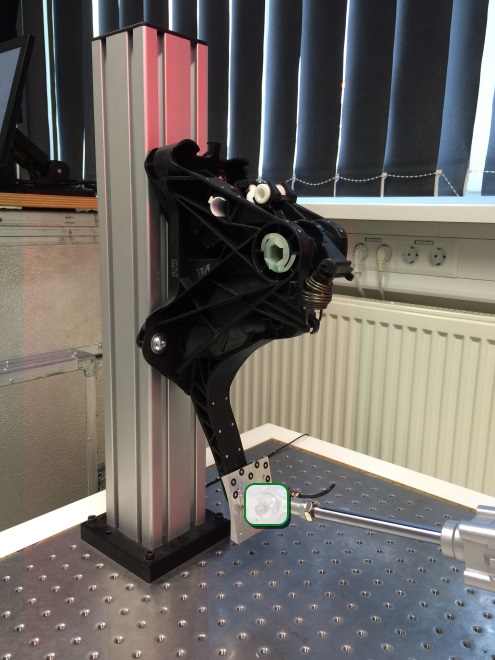

In this application example, the deformation of a plastic pedal is measured optically when a mechanical load is applied. The force is applied by means of a pneumatic cylinder. The force measuring pin is used as a joint pin between the joint eye of the cylinder and the bearing block on the pedal. It could easily be exchanged later for the original guide pin.

A stereo camera system follows the three-dimensional movement of the point marks applied to the pedal and the pedal block with high precision. The 3D measuring systems from GOM work contact-free and can be fully integrated into existing test devices, test benches or testing machines. The ARAMIS measuring system records static and dynamic deformations of material samples and components under mechanical or thermal stress – both selectively and extensively. Conventional strain gauges, displacement transducers or extensometers are therefore superfluous.

Evaluation:

The assessment of torsion, bending, displacement, velocity and acceleration factors enables the analysis of safety risks, component life, creep and aging processes, as well as the change in external appearance over life and in use. In particular, the main focus of this test is on the torsion around the vertical axis at the time of the highest load and on the determination of elastic or plastic deformation. The force and deformation data can also be displayed in real time and exported via SCPI command if required.

Advantages:

- Direct determination of the force without the influence of friction and lateral forces

- Simple hardware and software implementation of the force measuring bolt in the existing system

- Accelerate design and simulation processes or maintain quality standards

In cooperation with Gom mbH www.gom.com