General information on loadpin

Loadpin is a proven design element that has been used for more than 50 years in metrology. In older books it is also known as Vibrometer.

Today’s designations are:

- Force measurement

- Load pin

- Force measuring bolt/stud

- Measuring axis

- Force sensing bolt/stud

In English-speaking following terms are used:

- Loadpin

- Load Pin (both spellings are used)

General

Measurement principles

There are basically two methods of measurement principles in load pin. The first and most popular priciple is with strain gages, The second ist based on measurement of magnetic field.

For a resistor based measurement Weatstone bridge is used out of:

- Strain gages

- Thin film applied

In magnetic measuring a transformer circuit is built. As an iron core the hole load pin is used. Through the strain of the load pin the magnetic properties of the material changes and thus the voltage at the secondary coil.

Force fields

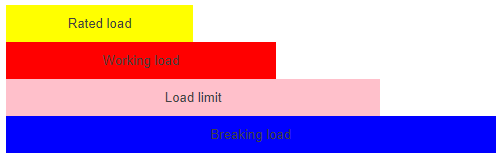

In all datasheets rated load, working load, ultimate load and breaking load are given. The description of this information shall be made in this approach.

Nominal force Fnom

Specifies the force to which the rated accuracy applies. That means, if forces applied which are below the nominal force, than the test results meets the specified accuracy.

Working Load Fu

Specifies the force up to which the load pin can be applied permanently. In this load range increases the uncertainty of the measurements. The results are useful, but not in the specified accuracy.

Load limit Fgr

Specifies the force up to which the load pin may be charged once, without the changes in the force measurement.(Occurring the load limit may shift of the zero point on)

Breaking force Fbr

On exceeding this load fracture risk.

Instructions for the correct assembly of load pins.

General

- Keep the certificates of loadpins with their documentation.

- Before assembling a load pin, check that the measuring range matches the requirements of the application.

- Make a note of the load loadpin serial number and place of installation in the documentation provided with it.

- Never use the cable to lift or handle the loadpin.

- Do not overstretch the cable of the loadpin.

- After the loadpin has been installed, you should avoid using welding equipment as the current flows directly through the cell or induction could destroy the cell. The risk can be reduced by connecting a flexible earthing cable( copper, about 1cm long) between the upper structure and the lower support of the cell.

It is always better to replace the load pin with a “dummy” in the adjacent area during welding work.

Wiring instructions

- If necessary, the connection cables must be protected by protective pipes.

- The cable of the loadpin must be laid separately from and at a reasonable distance from high voltage and power cables.

Ambient conditions

Temperature

The loadpin is normally calibrated for working temperatures of -10 to +40°C, at a limit temperature of -20 to +70°C. The loadpin can be calibrated for other temperature ranges upon request.

If sensors are used at temperatures of less than 0°C, they must not be cleaned with steam or hot liquids as this would cause condensation to form inside the loadpin.

Water, steam, etc.:

Loadpins are manufactured to a standard with a protection rating of IP 65 (other protection classes are available upon request.

Please ensure that loadpins are not used in situations where a higher protection class is required.

If the load pin is assembled in a recess a drainage pipe, bilge pump or other protective devices must be used.

Please ensure that the load pin is not soaked in water.