Attaching loadpins

A force loadpin must be attached in order to secure its alignment. Axial displacement must be secured first and rotation second. Proper securing is essential for obtaining accurate results. An axle holder pursuant to DIN15058 is used for this as standard.

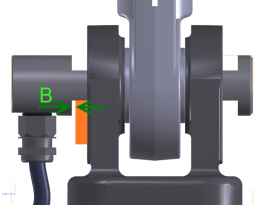

Axle holder assembly:

Axle holder grooves are designed pursuant to DIN15058 in most cases. This standard recommends using one axle holder for diameters of up to 100mm and two axle holders per force loadpin for larger diameters. For best results, leave a small gap between the axle holder and the axle holder groove. This will allow the loadpin to bend freely in the outer support.

Gap B should be approximately 0.2 mm.