Application: CNC Milling Machine

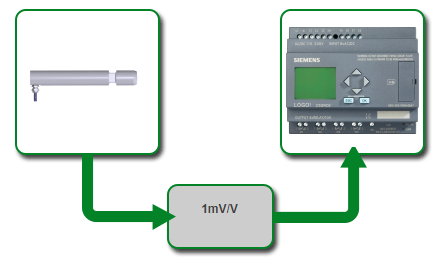

System interface: Integrated amplifier with analogue interface

Loadpin MB239 SPS

Target:

In order to allow a tool breakage detection, tool optimization and speed optimization a sensor system is essential. A perfect physical value to get information about the state of the machine is the force.

Previous solutions:

In the past, often been hydraulic pressure and electrical voltage used as an indicator of the current state of the maschine. These downstream physical quantities are often fragile for disturbances such as wear and friction.

Retrofitted with loadpin:

The subsequent use of force sensors is not always easy. Existing constructions which are otimized in many years, are not easily fitted with a force sensor system. Loadpin provide an easy way to integrate tool breakage detection and tool optimization into existing systems. There for a given an existing torque arm and its lock is provided with a loadpin.

Advantages:

- High natural frequency by stiffness of the measuring loadpin

- Possibility of the tool and feed rate optimization

- Direct process factor monitoring

- Retrofit tool monitoring and tool breakage protection

Alternative loadpins: