Application: Pneumatic cylinder

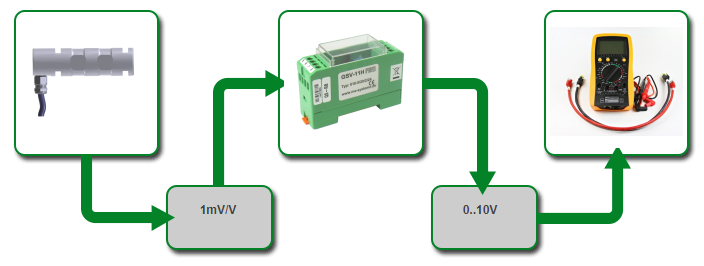

System interface: External amplifier with analogue interface

Loadpin MB254 Amplifier GSV-11H Multimeter

In automatization, pneumatic cylinders are widely used. They are used for positioning, holding and moving the respective goods. In certain quality-related production processes, the pneumatic force have to be recorded very precise. One opportunity is to measure the pressure. But with this method errors are possible. Additional forces can be generated by sticking friction in the cylinders – which do not bear on the workpiece. The measurement of tensile forces is not possible with simple pneumatic cylinders.

The most important point of force transmission in an pneumatic cylinder is the swivel head. It is possible easisly to integrate a loadpin for force measurement. It isnot nessesary to redesign or reconstruct anything. With this method it is possible to measure different directions of force. For the need of safety relevant applicattion the loadpin can be made in a redundant design.

Examples:

- Measurement and control of forces at pneumatic press-in processes

- Control of push processes in automatization

- measurement of forces at pneumatic grabber

Advantages:

- No reconstruction

- No sticking friction

- Integration of overload cut-off

Alternative loadpins: